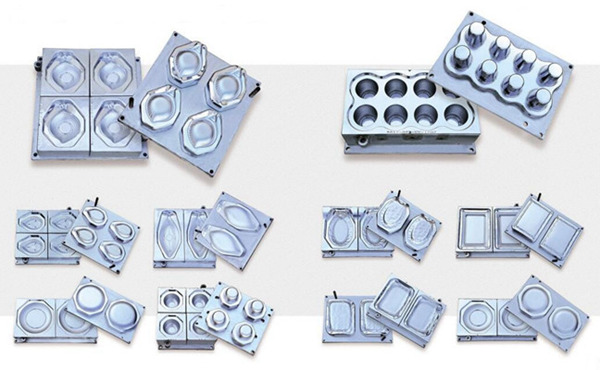

The reasonable structure design can ensure the service life of the mold, therefore it's the foundation for molds. Shunhao Machine and Mould Factory has lots of successful cases in melamine compression molds making. Since 2002 customers from 30 more countries recognize and have been maintaining long-term cooperation with Shunhao.

In order to make sure the mold working for a long service time, the molds making must obey the following 3 rules.

1. Good casting structure design

2. Reasonable mold structure design

3. Standardize the heat treatment process